What Are Beadlocks?

Tires: Milestar Patagonia M/Ts

What are beadlocks, and what do they do? You might have heard the term beadlock used or seen the unique wheels on an offroad vehicle. Beadlock wheels are used in several types of racing, especially on dirt. Their look is distinctive due to the circle of bolt heads that run around the face of the outer rim. They look so good that many wheel manufacturers have copied the look without using the actual locking bead design. It gives any vehicle a purpose-built offroad appearance.

Tires: Milestar Patagonia M/Ts

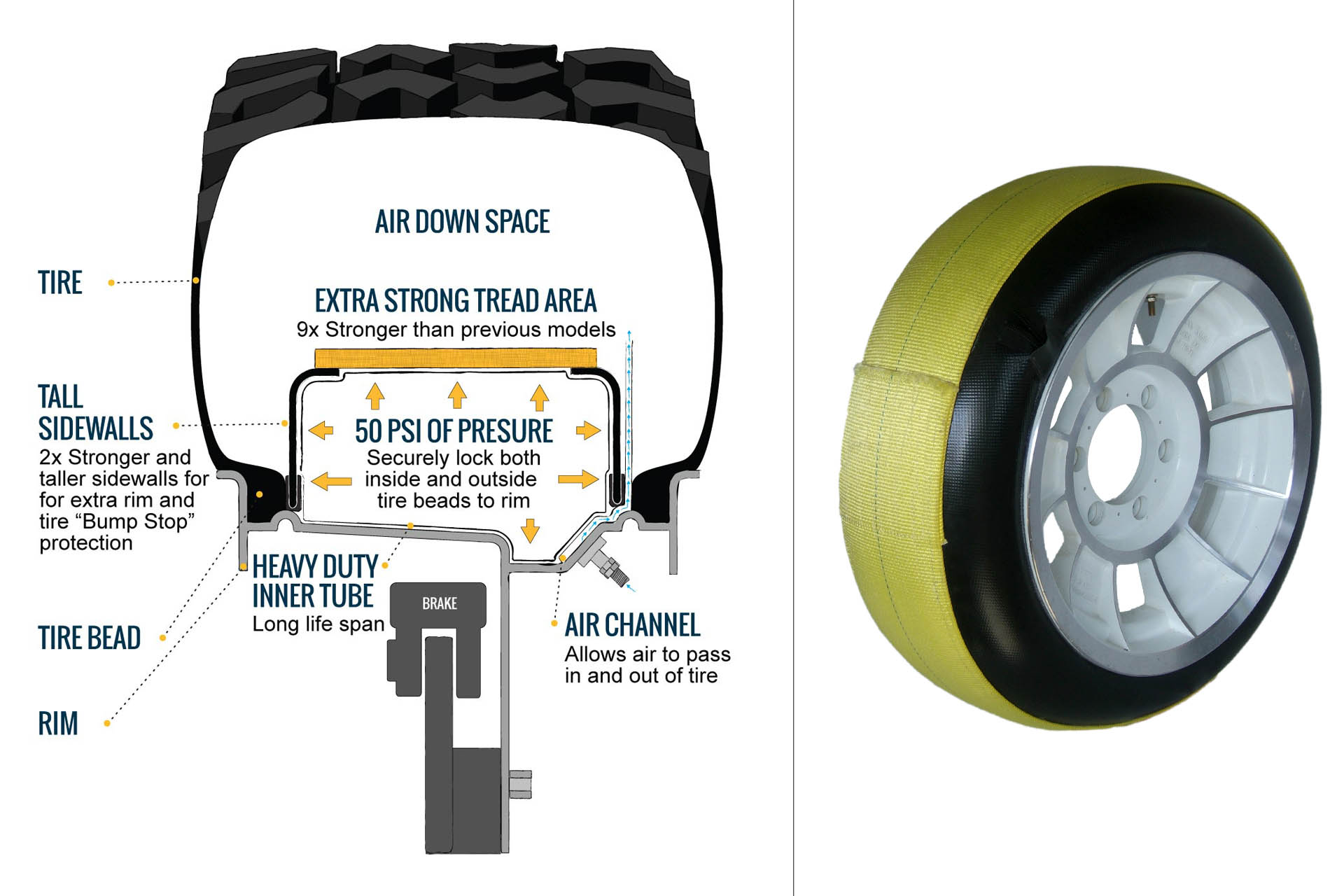

Real beadlock wheels provide an important function; they keep the tire bead locked to the rim. Typically the air pressure in your tires forces the tire bead into the lip on the wheel creating a seal that holds the air pressure in the tire. That design works well on the pavement where full air pressure is needed. When air pressure is too low on pavement, excessive heat is created, and tire failure is possible. Offroad vehicles sometimes run lower air pressure in the tires to allow a much larger contact patch on the ground; increasing traction. In deep sand and snow, the larger contact patch helps the tire to float on top instead of digging in which can get you stuck. Lower air pressures offroad will also give you a smoother ride, and allow the tire to flex over sharp rocks. A little give in the tire can prevent punctures from sharp rocks, especially in the sidewall. When rubber goes against rock, the rock usually wins. If you are going to run lower pressures, a beadlock wheel is necessary to prevent the tire from spinning on the wheel, or from losing air pressure all together. Once the tire bead becomes unseated, the tire can get damaged, and all traction is lost. If the tire comes apart, it can wrap around the suspension, rip off your brake line, or cause other damage to your shocks, steering, or body panels.

There are several types of beadlock wheels available. The most common style is the bolt-on outer ring. This style has a machined lip on the outside of the rim to locate the tire bead. Once the tire is slid onto the wheel, the outside tire bead rests on the machined lip. The locking ring then goes on top. Bolting the ring to the wheel clamps the tire bead to the rim and creates an air tight seal.

Tires: 37″ Milestar Patagonia M/Ts

Tires: 37″ Milestar Patagonia M/Ts

Event: Friends of Steve Mcqueen Car Show 2018

Military wheels use a different design. Instead of the ring clamping the bead to the wheel, they are more of a two-piece wheel with a cylinder that slides over the barrel of the rim. The tire goes on the wheel first. Then the cylinder is slid over the wheel inside the tire. When the outer rim half is bolted down, it clamps the inner cylinder between both inner and outer beads of the tire. The width of the inner cylinder needs to be matched to the thickness of the tire beads in order to work as desired.

Source: Coyote Enterprises

Similar to the military style in concept, as it clamps both beads to the rim, a third design uses an inflatable bladder inside the tire. The bladder sits inside the tire on the barrel of the rim. Once inflated, it pushes out on both tire beads. This style can be used on most non-beadlock wheels. All that is needed is another valve stem added to the wheel in order to fill the bladder.

Tires: 40″ Milestar Patagonia M/Ts

No mention of beadlocks is complete without discussing the elephant in the room. Every automotive forum online has a thread discussing whether or not beadlocks are street legal. Maybe the confusion comes from the old style wheels known as split rims. Split rims have a ring that sits between the tire bead, and a slight lip on the outside of the wheel. Air pressure seats the split ring against the lip on the rim. Split rims are notorious for coming apart when air pressure pumps up the tire. When they were used, the rim and tire were placed in a steel cage to contain the flying parts if the ring flew off. People were injured; even killed by split rims. That’s why they were phased out. The split rim is still used on heavy equipment tires, but you will not find them on anything but vintage vehicles. Most tire shops refuse to work on them. Tire shops don’t like beadlocks either, but one of the benefits of the beadlock design is that you can mount tires without any special equipment.

Tires: 40″ Milestar Patagonia M/Ts

Beadlock rings are not illegal, but they can be dangerous if proper diligence is not used.

Tires: Milestar Patagonia M/Ts

Tires: Milestar Patagonia M/Ts

Generally, there are no laws that specifically outlaw beadlock wheels. At the same time, they do not satisfy the standards that have been adopted by many wheel manufacturers due to their multi-piece design. Beadlock rings are not illegal, but they can be dangerous if proper diligence is not used. Care needs to be taken during assembly. If the bolts are overtightened they can stretch, and fail. If they are not tight enough, the tire can move, and lose pressure. It’s important to tighten the bolts evenly, and to the correct torque value. Each manufacturer has their own standards depending on the bolts used, and the construction of the wheel. Some beadlock wheels have threaded steel inserts for the bolts. Other wheels have been heat treated to a condition that makes the aluminum able to hold a thread. Of course, there are steel beadlock wheels as well. If the tire bead is very thick, spacers may be needed between the rim and the beadlock ring. You don’t want a gap between the ring and the wheel as the tire bead can still flex. The bolts need to have the proper torque on them in order to work. If the bolts fail, the ring can fly off; a dangerous condition.

Tires: 37″ Milestar Patagonia M/Ts

Once you get the hang of it though, it’s really simple. That’s another benefit of the beadlock design. If you get a flat tire, you can take the wheel apart, patch the tire, and then put it back together in the field. It will take some work; most beadlock wheels have 20 to 30 bolts. Another benefit of the ring style beadlock is the ring itself. It adds strength to the outer lip of the wheel. If you are grinding your wheels in the rocks all the time, you can replace the rings when they get gouged or worn down. When you look at the pros, and cons, beadlocks have a lot to offer on an offroad vehicle.

Tires: 37″ Milestar Patagonia M/Ts