10 Engines That Changed the World

We take a lot of things for granted today – engines that start with the turn of a key, deliver abundant horsepower from minimal displacement, squeeze every mile possible out of a gallon of gas, and run for a hundred thousand miles and beyond with only routine maintenance. But over the last century or so, there have been some definite turning points where new technology and fresh ideas have radically changed how we drive. Here’s a look at ten of them that deserve recognition.

Ford Model T – 1908

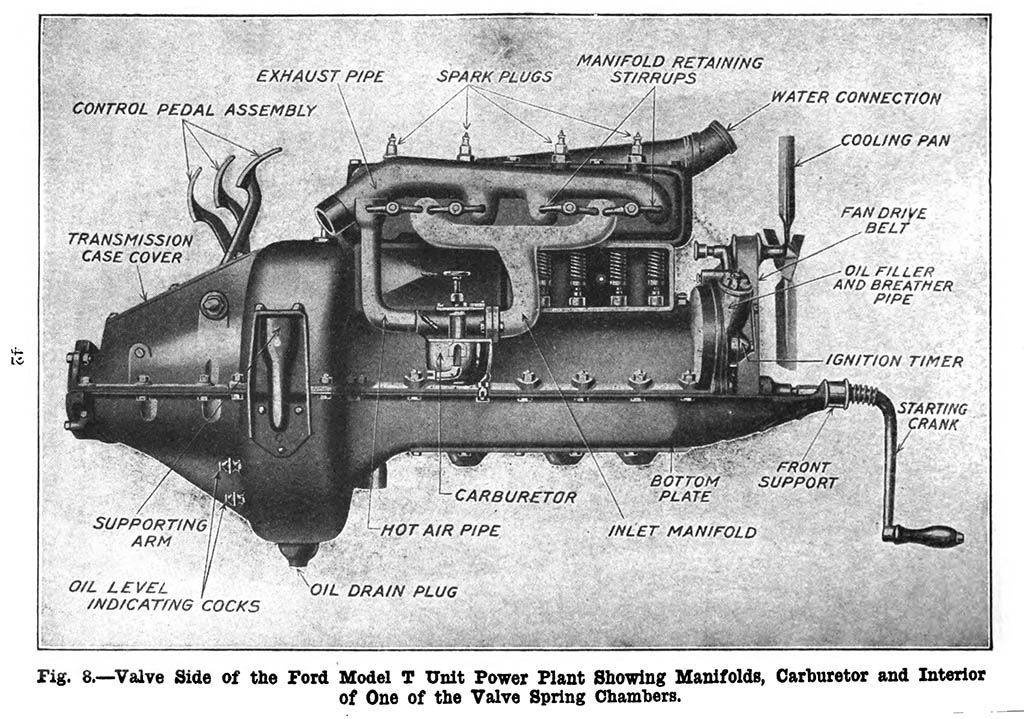

Henry Ford’s car for the masses was one of the few vehicles in history that actually got simpler and cheaper over its long production run, and the basic 144 cubic inch inline-four under the hood, delivering a whopping 20 horsepower, was the perfect powerplant for the job. With a 3.98:1 compression ratio, this side-valve engine wasn’t all that sensitive to fuel quality, which was an important selling point in a world where the availability of highly-refined gasoline was pretty much non-existent.

Everything about the Model T’s engine was simple by design. There was no fuel pump, with the single sidedraft carb relying on gravity feed much like a lawnmower engine, and spark was provided via magneto and four “trembler” coils to step up the voltage. After an initial short run of a few hundred engines equipped with a water pump, Ford switched to a ‘thermosiphon’ cooling system that relied on the natural circulation of hot water. Hand crank starting was supplemented with an optional electric starter in 1919.

Although Model T production ended in 1927, the engine continued to be manufactured all the way up through the fall of 1941 for use in industrial and marine applications to power pumps and generators.

Ford Flathead V8 – 1932

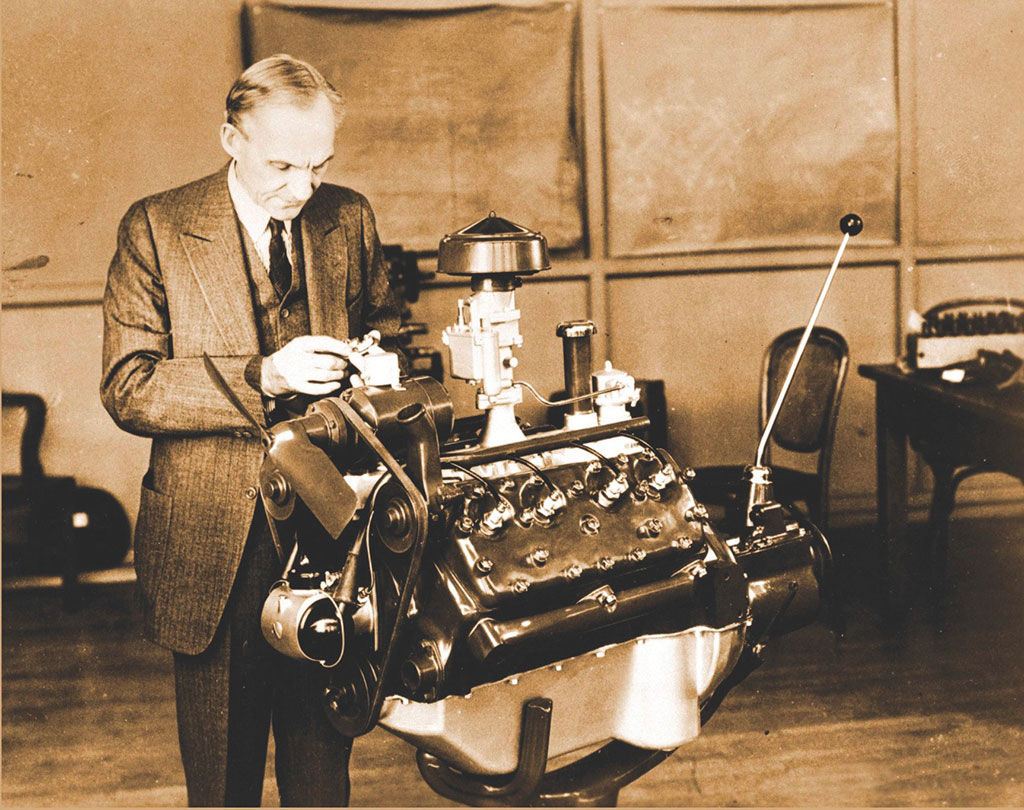

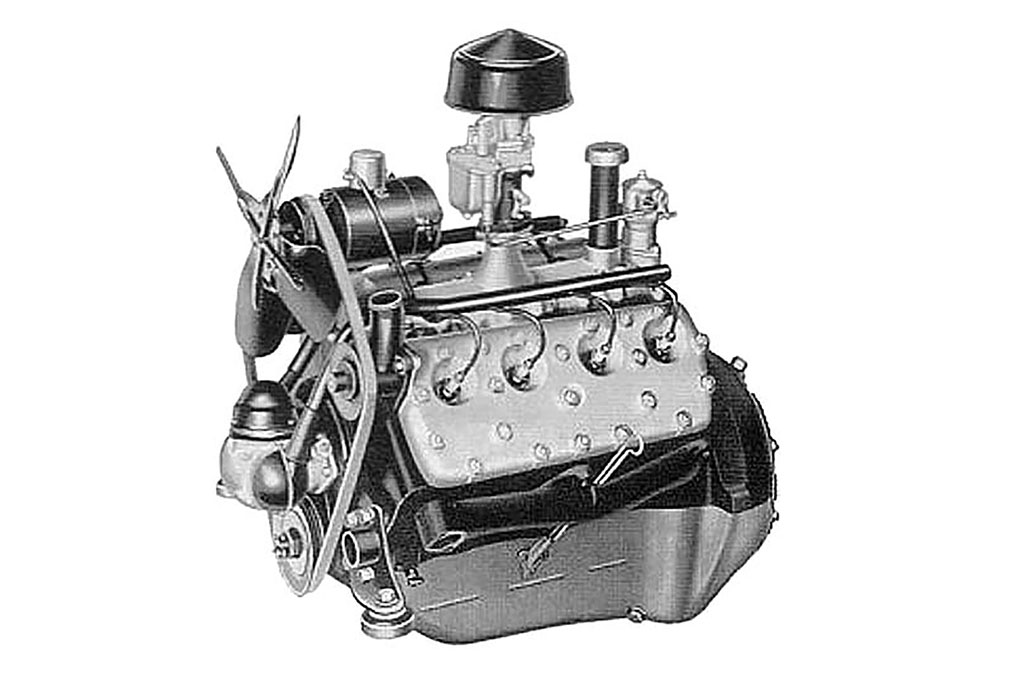

Though the V8 engine configuration, with two banks of cylinders sharing a single case and crankshaft, dated back to the turn of the 20th century, Ford’s original 221 cubic inch “Flathead” V8 was revolutionary in 1932. Most widely-produced car engines up until that time were either inline four or six cylinder designs, and even luxury cars with powerful (for the time) eight cylinder engines almost always were inline block layouts. The relatively compact Flathead was initially rated at 65 horsepower, then improved via an increased compression ratio to 85, and the design morphed into a number of different displacements ranging all the way up to a 337 cubic inch version and shrunk down to a diminutive 60-horsepower 136CI model.

Despite having cooling issues stemming from the necessity of routing exhaust passages through the block, and the general inefficiency of the valve-in-block cylinder head design, it’s impossible to understate just how important the Flathead was as an automotive powerplant. It was the engine that spawned the original hot rod movement, and countless aftermarket performance parts, up to and including overhead valve “Ardun” cylinder head conversions. Eventually overshadowed by more modern V8 engine designs, the Flathead still remained in production (albeit in highly-modified form) all the way up until the mid-1960s, and it continues to be popular with hot rod builders interested in retro or period-correct power.

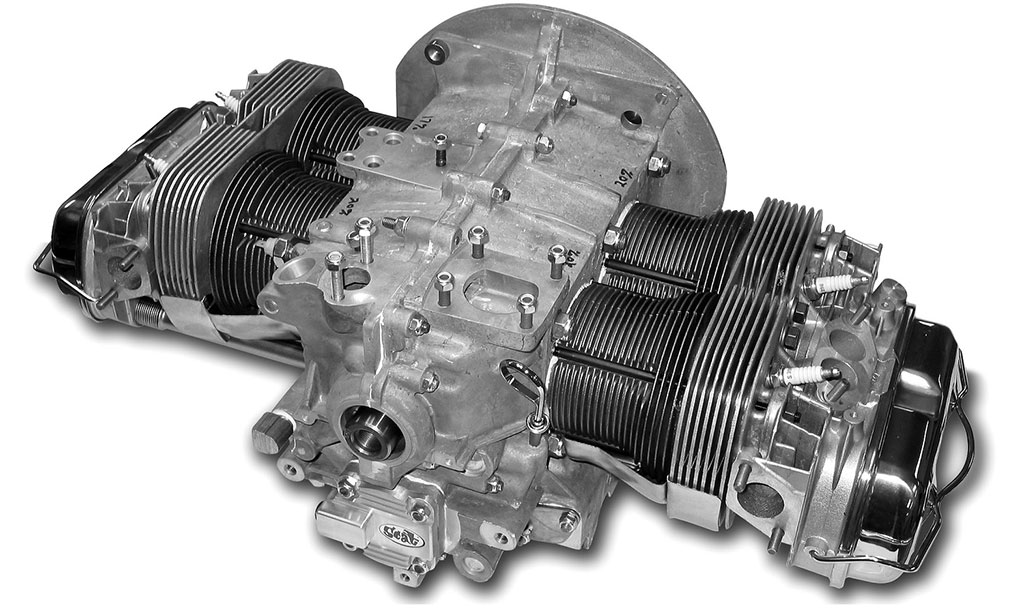

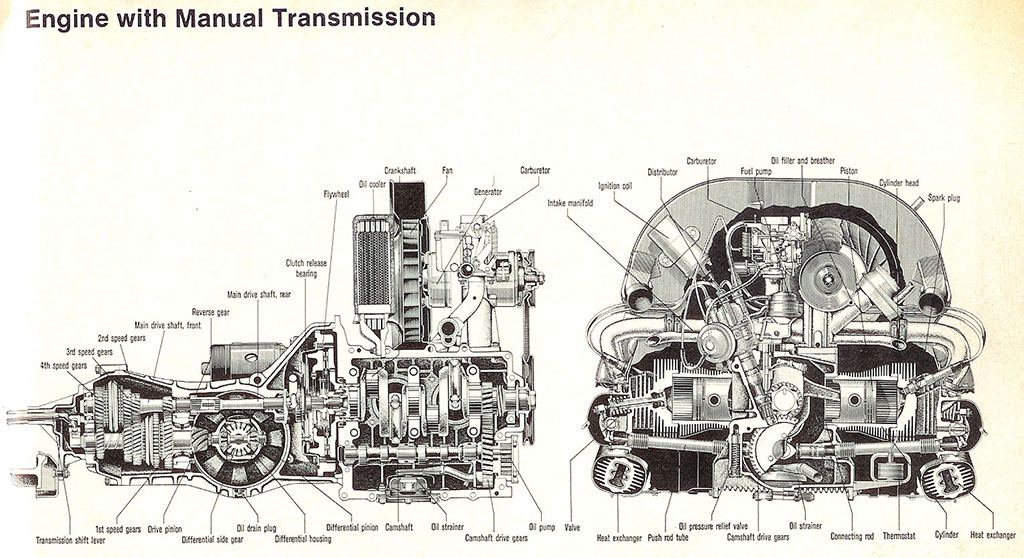

Volkswagen Flat Four – 1936

Designed during the era of German nationalism that metastasized into the Nazi Reich, the horizontally-opposed, air-cooled flat-four engine from the “people’s car” ended up powering decades’ worth of vehicles that became synonymous with peace and love, and remained in factory production for more than 50 years, eventually spawning a water-cooled successor and laying the groundwork for Porsche’s legendary aircooled 6-cylinder “boxer” engines.

Despite its uber-simple design, which utilized a horizontally opposed layout to make it as compact as possible and fan-driven air cooling to eliminate the need for complex castings incorporating passages for liquid coolant as well as the weight of a water pump and radiator, the VW flat-four featured some remarkably sophisticated engineering for the era. The heads were manufactured from aluminum, while the finned cylinders were cast iron, and the crankcase was made from lightweight but strong magnesium.

With displacements ranging from 1.0 to 2.0 liters, and horsepower ranging between 24 and 99+ in factory trim, the VW flat-four found its way into a lot of vehicles other than the iconic Beetle – vans, the mid-engine Porsche 914 and “entry level” 912, countless dune buggies and kit cars, and even aircraft. As a matter of fact, its similarity to the widely-used Continental and Lycoming horizontally-opposed air cooled aircraft engines led not only to conversions for experimental kit planes, but even certified versions for aviation use. Its simplicity, durability, and tuner-friendly nature mean that the VW aircooled four will be popular for as long as internal combustion engines still exist.

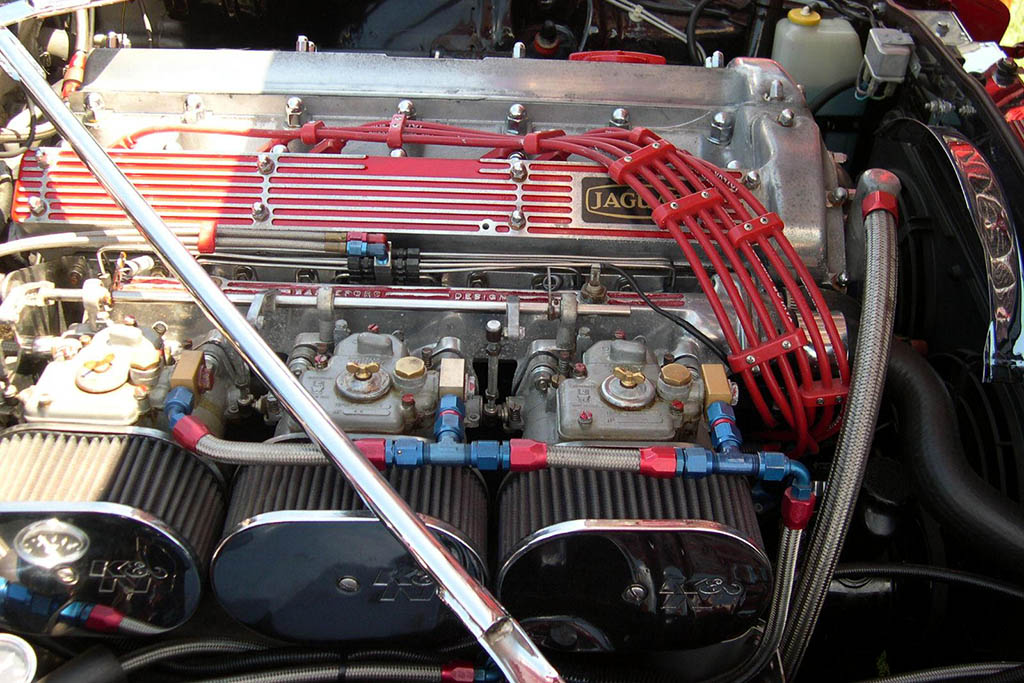

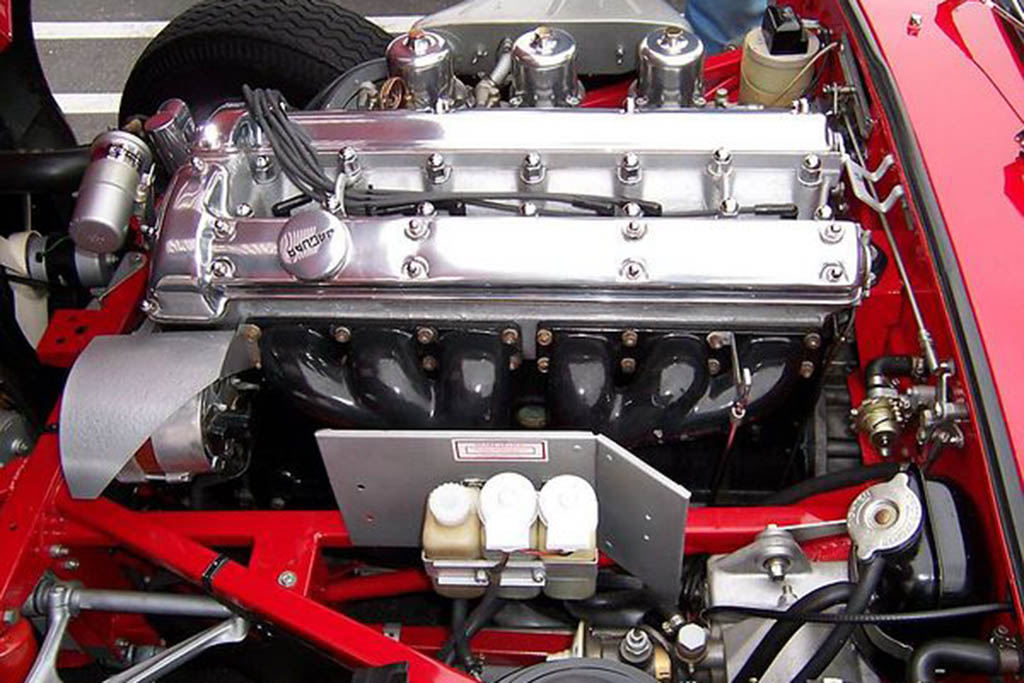

Jaguar XK6 – 1948

There were inline-six engines before the Jaguar XK, and there were dual overhead cam engines before it as well. But the 3.4L engine that first appeared in the Jaguar XK120 sports car (their first sporting model since the unpleasantness on the Continent ended production of the SS100 in 1939) was the engine that all subsequent I6 designs and all DOHC powerplants of any cylinder count worth mentioning can claim as an ancestor.

When Nissan, Toyota, and even BMW set out to build their own I6 powered sports cars, the XK6 provided the archetype, so if you are a fan of the RB, 2JZ, or M30, you owe a debt of gratitude to this seminal design.

The XK6’s iron block was topped by an aluminum cylinder head; the material had been selected not only for light weight but also for its ability to efficiently move combustion heat into the cooling system, which allowed a higher compression ratio without detonation (and took advantage of the massive increases in fuel knock resistance that the war had brought). Widely-spaced, large valves and ports designed to increase intake charge swirl let it breathe, and the XK6 quickly went from a rated 160 horsepower to 210, then 250.

The Jag 6 was the result of a generation of engineers who had been pushed hard for a decade to defeat an existential threat to their nation turning their now-razor-sharp skills on making the best auto engine they possibly could, and between 1948 and the end of its run in 1992, the design in all its variations and displacements made its way into dozens of different Jaguar models, and even powered the Scorpion and Scimitar armored fighting vehicles.

When Nissan, Toyota, and even BMW set out to build their own I6 powered sports cars, the XK6 provided the archetype, so if you are a fan of the RB, 2JZ, or M30, you owe a debt of gratitude to this seminal design.

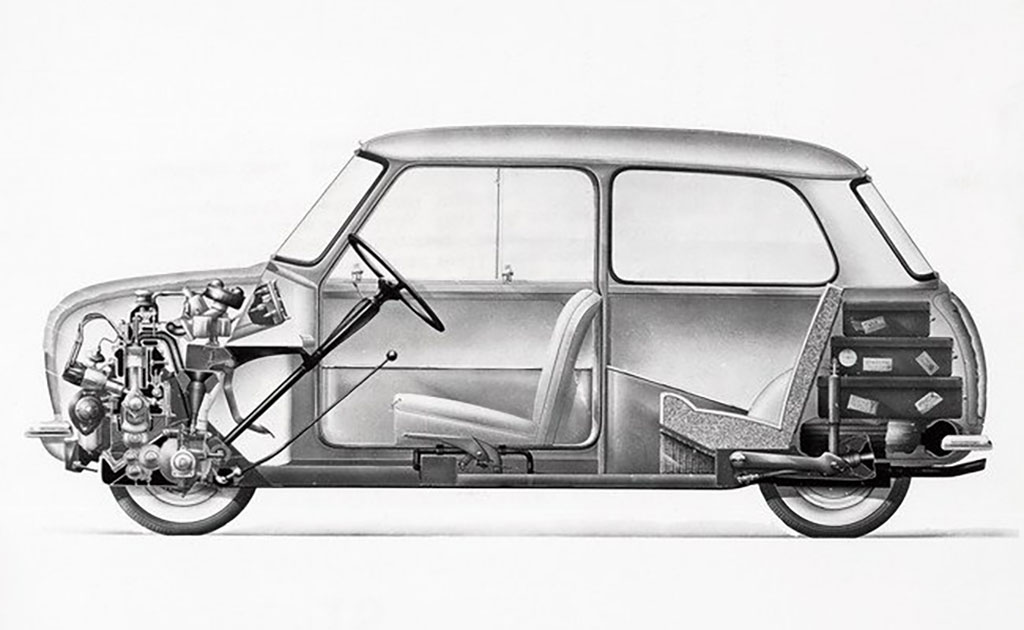

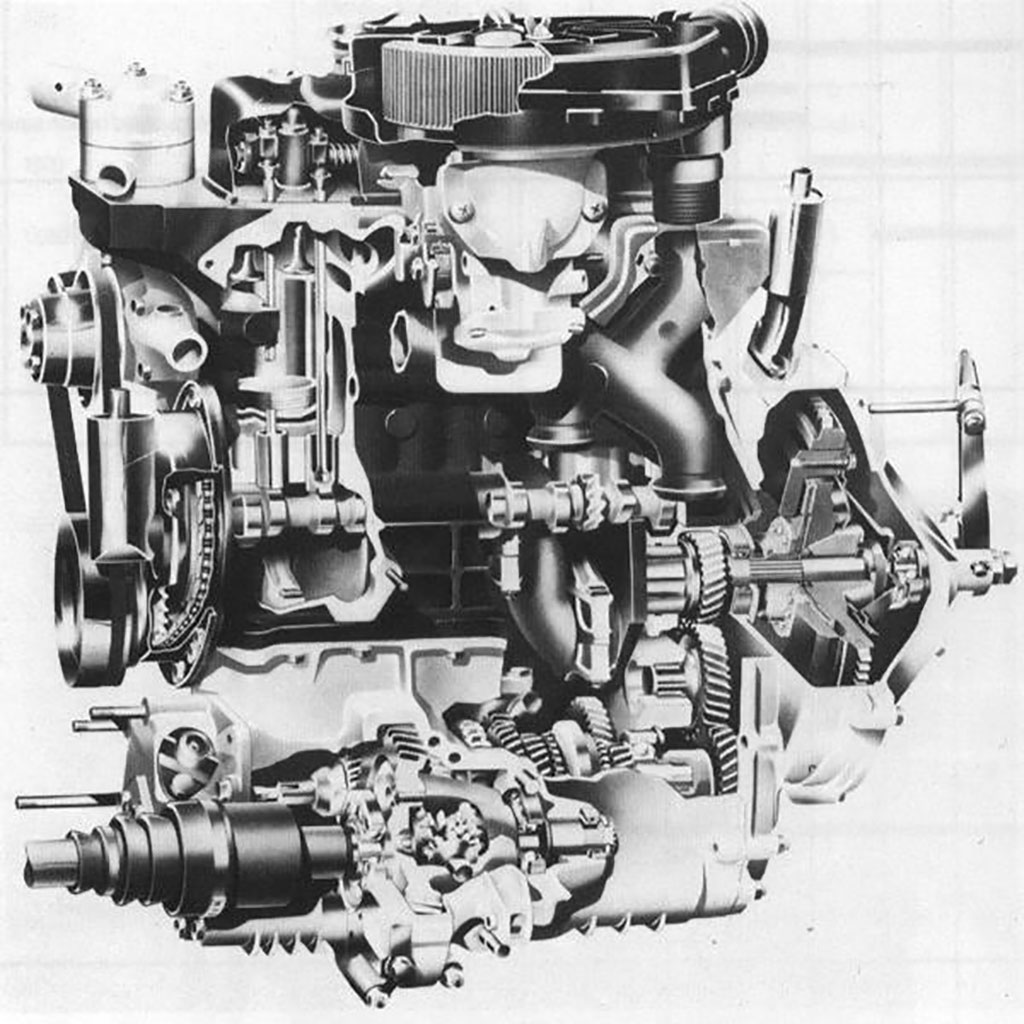

BMC A-Series – 1951

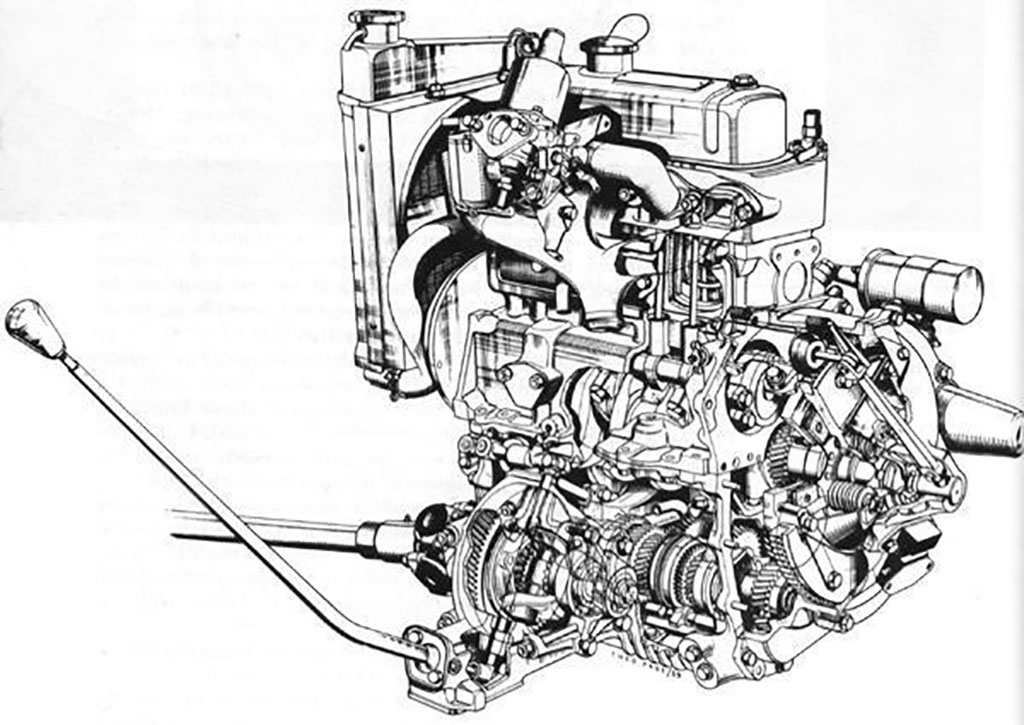

The Austin Mini holds pride-of-place as the car that first put together all the elements of the modern automotive transportation appliance in the same package: All the bulky mechanical parts out ahead of the passenger compartment, with a transaxle powering the front wheels driven by a transverse inline-four engine. The diminutive car required a similarly-tiny engine, and the BMC A-Series, ranging in displacement from 0.8 to a whopping 1.275 liters, was the perfect companion.

While outside of Japan’s Kei sub-sub-compacts, almost every other FWD car is huge compared to the original Mini, but they all draw inspiration from it. Nissan’s CA family can show a direct engineering family tree to the BMC A-Series, having been built around a licensed version of the little Austin’s blueprints. The A-Series inline four wasn’t anything particularly revolutionary in terms of performance or mechanical engineering, but it led the way in how engines would be packaged in the future to free up maximum space for people and things on the inside of the vehicle, making an impact on the automotive world that was as enormous as the engine itself was small.

Chrysler Hemi – 1951

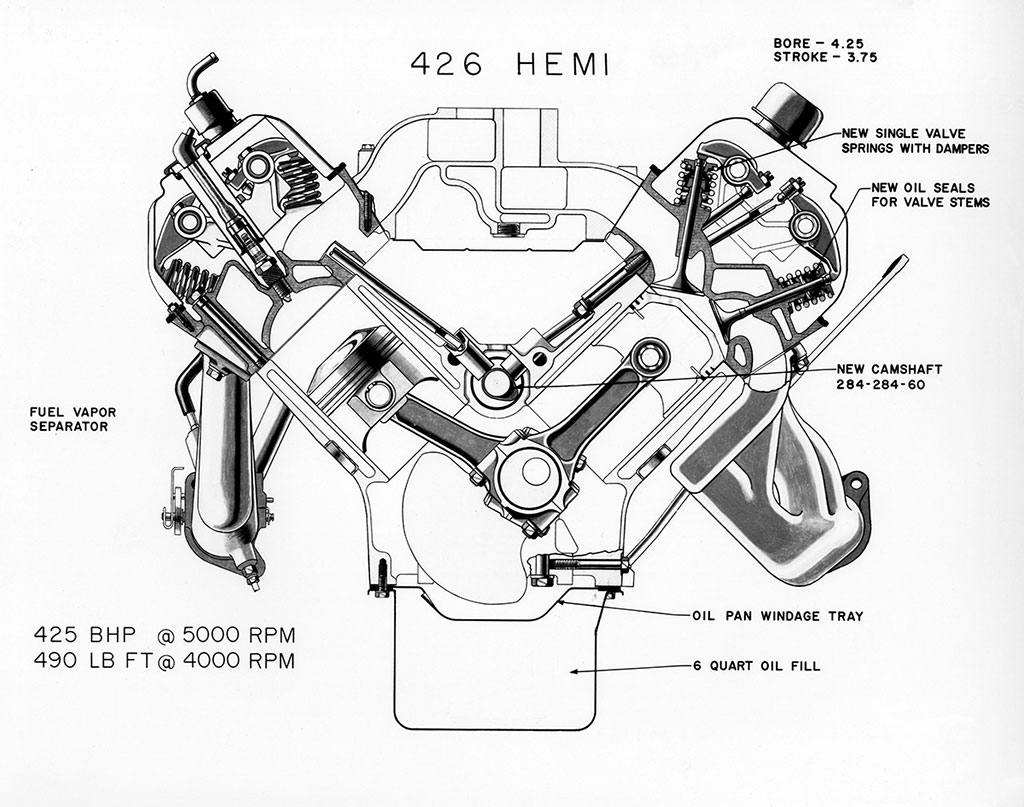

Born from an experimental aircraft engine design that reached maturity just a bit too late to contribute to the Allied war effort in 1945, Chrysler’s hemispherical cylinder head concept was, at heart, the engineering solution to the problem of fitting the biggest possible pair of valves into any given cylinder bore diameter. Once civilian car production re-started, the company took what they had learned in developing that engine and applied it to their FirePower 331 cubic inch V8 that debuted in 1951, delivering between 180 and 300 rated horsepower depending on configuration.

Thanks to the design’s wide bore spacing, displacement grew throughout the decade, and DeSoto Fire Dome and Dodge Red Ram and Power Dome versions of the same architecture were introduced. But the second-gen Hemi, introduced in 1964 and displacing 426 cubic inches, was what put the name on the performance map. The over-the-counter version available to the driving public from 1965 to 1971 was rated at 425 horsepower (gross, with no accessories like a water pump drive or alternator to put parasitic drag on the engine) and 490 pound-feet of torque. In competition, NASCAR and professional drag racing teams embraced the enormous (and enormously powerful) Hemi, and there are still traces of the original 1964 Hemi DNA in today’s nitromethane-burning supercharged Top Fuel and Funny Car engines.

While the name was revived (rendered in all caps – “HEMI” – don’t you forget it!) for a third generation in 2003 that continues in production today, the engine bears little resemblance to its forebearers – a true hemispherical combustion chamber as seen in the second-gen engines, while allowing very large valves, ends up with a “squish” space that looks like an orange peel. This makes the design sensitive to fuel quality and ignition timing to make sure that large, thin volume of compressed gas and air burns smoothly and completely. Modern multi-valve “pent roof” cylinder heads with four facets for a pair of intake and exhaust valves, plus a fifth for the spark plug, achieve the same airflow advantages of a two-valve Hemi head while allowing more efficient combustion chamber shapes. Nevertheless, Chrysler’s Hemi remains as an iconic turning point in performance engine design.

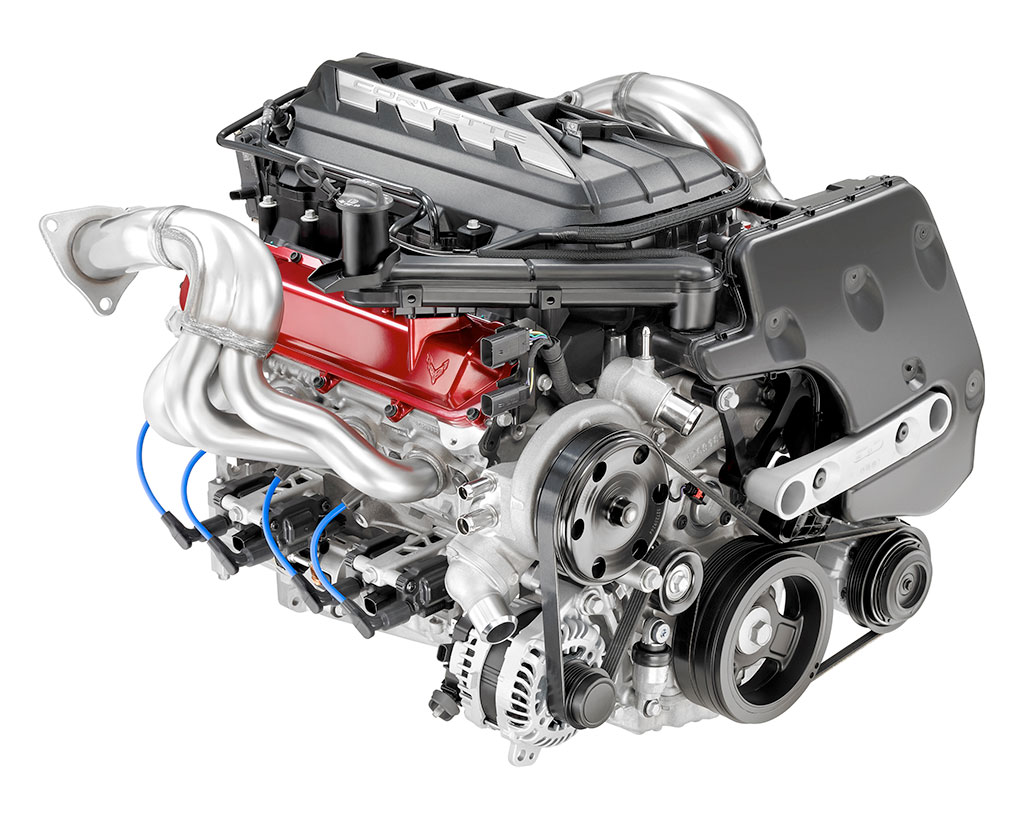

Small Block Chevy – 1954

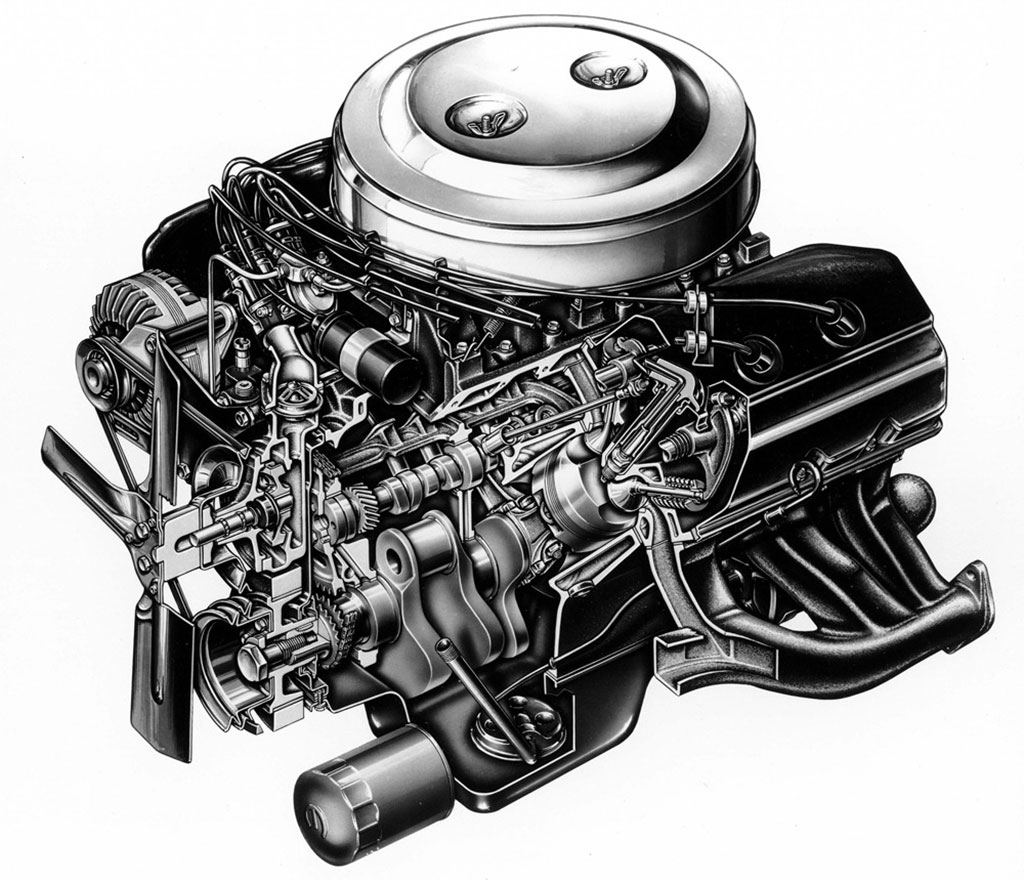

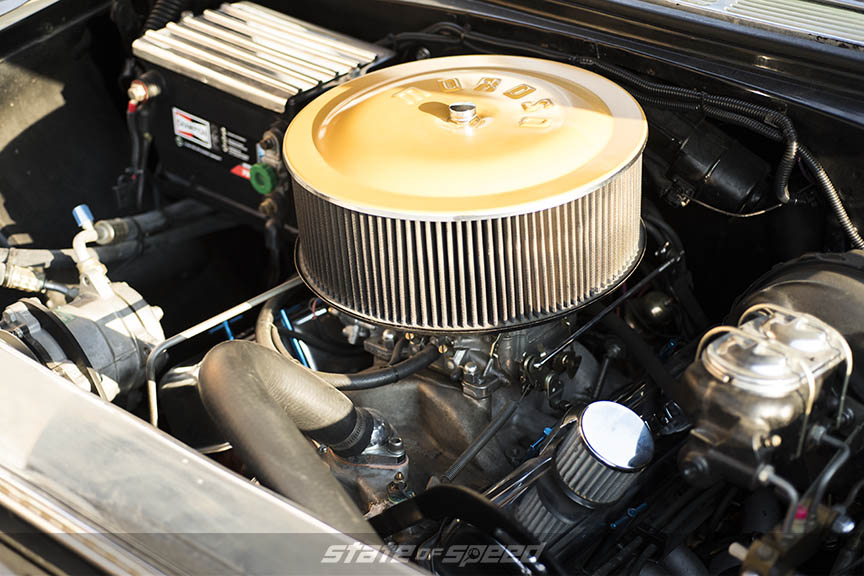

Arguably the most popular engine of all time, the original “small block” Chevy V8, first introduced in the 1955 model year Corvette and Bel Air, caught lightning in a bottle, and its descendants continue to be manufactured today for use in cars like the mid-rear-engine C8 Corvette. Unlike the Flathead, Chevy’s V8 utilized an overhead-valve cylinder head that allowed for higher compression, a more efficient combustion chamber design, and improved cooling.

The original 265 cubic inch design eventually grew into 400CI factory engines with the same bore spacing, and the SBC was one of the first production engines to deliver more than one horsepower per cubic inch of displacement. Over five separate generations, there have been countless changes to the original Chevy V8, including various mixes of cast iron and aluminum blocks and cylinder heads, distributor-fired and coil-per-plug ignition, carburetors, mechanical fuel injection, and EFI, and even cylinder deactivation for “displacement on demand” and variable valve timing.

The original 265 cubic inch design eventually grew into 400CI factory engines with the same bore spacing, and the SBC was one of the first production engines to deliver more than one horsepower per cubic inch of displacement. Over five separate generations, there have been countless changes to the original Chevy V8, including various mixes of cast iron and aluminum blocks and cylinder heads, distributor-fired and coil-per-plug ignition, carburetors, mechanical fuel injection, and EFI, and even cylinder deactivation for “displacement on demand” and variable valve timing.

Through all these changes, from the original 162 horsepower Gen I in 1955 to today’s naturally aspirated Gen V LT2 rated at 490 horsepower in the 2020 Stingray and the 638-horse supercharged Gen IV LS9, the SBC has retained one archaic design feature (with the exception of the unique Lotus-designed DOHC 1989-1995 LT5) – a single cam located in the center of the vee, with pushrod valvetrain actuation. In a world dominated by overhead cam designs, GM’s venerable cam-in-block design continues to prosper in everything from trucks to sports cars.

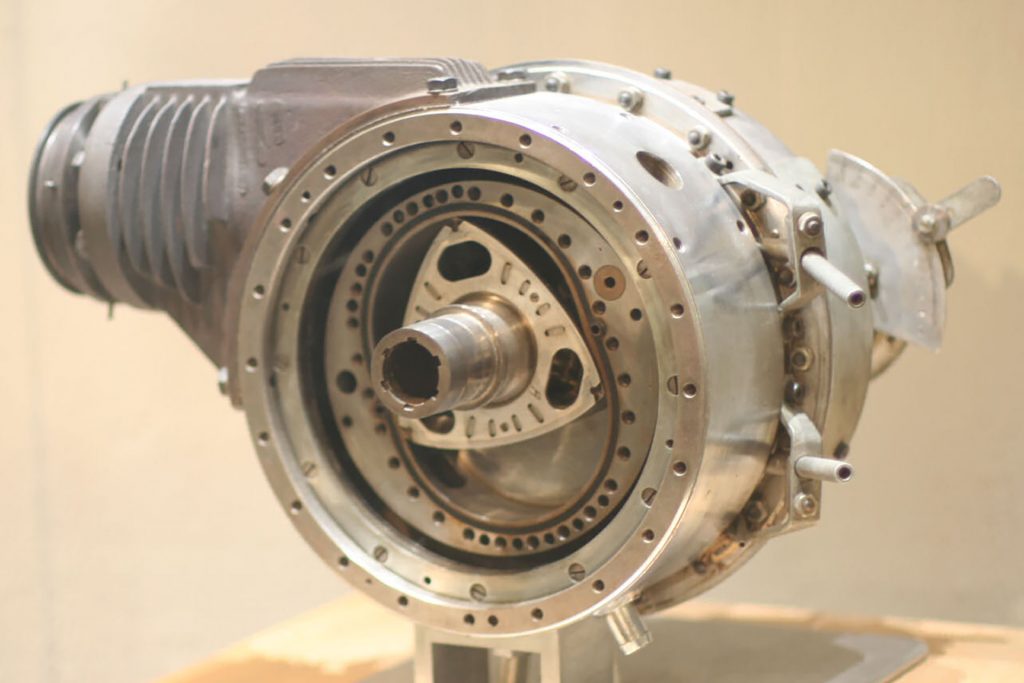

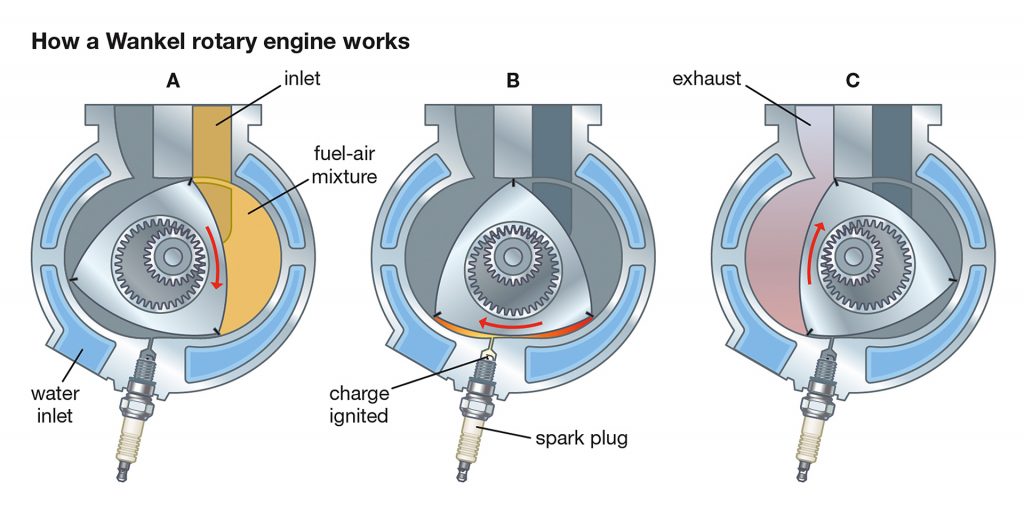

Wankel Rotary – 1964

Out of all the engines on our list, the Wankel is definitely the most revolutionary (pun intended). Forgoing the conventional piston-engine layout, the design originally conceived by Felix Wankel and patented way back in 1929 is a graduate-level education in geometry and physics. Instead of reciprocating, all the internal components in a rotary spin in the same direction, and although it operates in the same general way a four-stroke piston engine does, it has the power delivery characteristics of a two-stroke, with one power “event” per turn of the output shaft for each rotor assembly.

Tires: Milestar MS932 Sport

…but whenever there’s a need to pack a huge amount of horsepower in a high-RPM engine the size of a pony keg, the Wankel is ready to answer the call.

Tires: Milestar MS932 Sport

German manufacturer NSU was the first to bring a semi-practical design to mass production, but it took Mazda to really embrace the Wankel, licensing the patents and working out many of the unique challenges posed by the design, which included developing combustion seals for the rotor apexes and between the rotors and housing sides that would be durable enough to compete with piston engine technology that had several decades’ head start. Legendary Mazda cars like the Cosmo, RX-2, -3, -4, -7, and -8, and even a compact pickup (which was singularly unsuitable for rotary power in practical terms, but an awesome example of Mazda’s “Wankel all the things!” enthusiasm) featured rotary power, and many US manufacturers considered using variations of the design for everything from subcompacts to Corvette concepts.

Unfortunately, some inherent drawbacks remained hard to overcome – apex seal lubrication required a small, but continuous consumption of oil as there was no crankcase to separate lube from the combustion process, and although Wankel rotaries are very compact and mechanically simple compared to piston engines that deliver the same power, they’re also thirsty thanks to the thermodynamic inefficiency of their continuously variable combustion space. In the end, even Mazda more or less gave up on rotary engines for production vehicles, but whenever there’s a need to pack a huge amount of horsepower in a high-RPM engine the size of a pony keg, the Wankel is ready to answer the call.

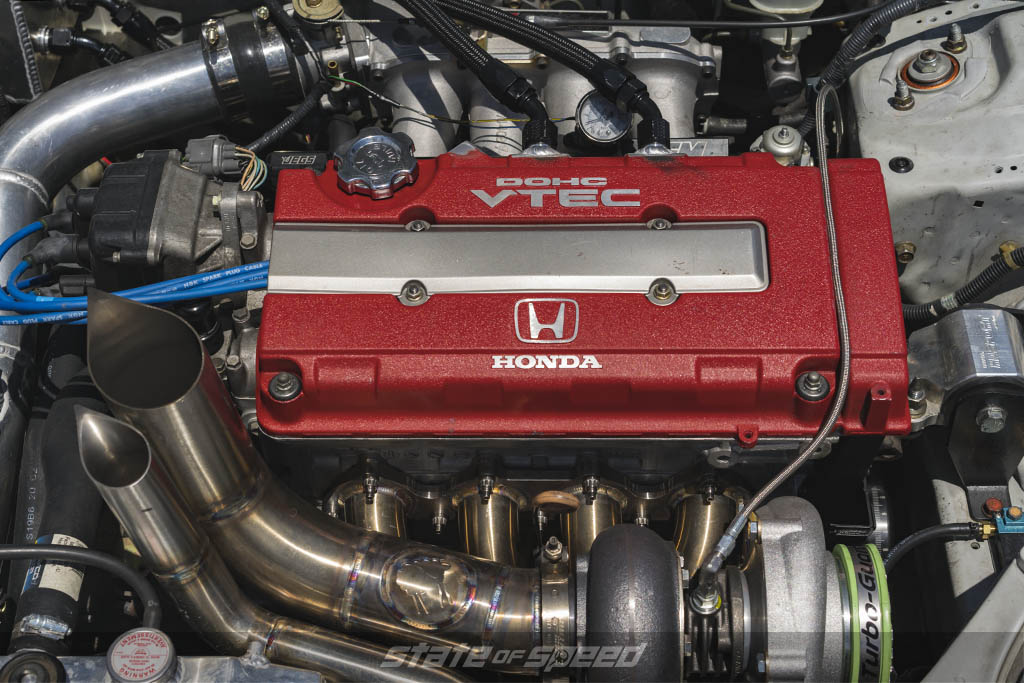

Honda B-Series – 1988

Where would a list of the Ten Engines that Changed the World be without the Honda B-series? For one thing, the author would be risking violence at the hands of a pitchfork and torch wielding mob of Honda fans, but this particular inline four earns its place on merit. It’s arguably the most-popular modern inline four in history, and it combined all the features and technology we take for granted in high-tech engines today. Although it was never intended for turbo– or supercharging, it proved itself to be readily adaptable to boost, and there’s no small-displacement engine family that can boast as much aftermarket support as Honda’s killer B.

With displacements ranging from 1.6 to 2.0 liters in factory trim and rated horsepower from 126 to 190, there were a wide range of variations in both short and tall deck versions, with a panoply of different details like cylinder head design. But the big thing Honda gave the world with the B-series was the widespread introduction of VTEC, their term for a system to switch cam profiles through the use of a hydraulically-actuated cam follower setup. Activated by a signal from the ECU, VTEC allowed the engine to flip between valve timing, lift, duration, and overlap optimized for fuel economy to higher performance and back again, foreshadowing all the current variable valve control technology incorporated into state of the art engines today.

Like the Ford Flathead and classic Small Block Chevy, the Honda B-series has become a favorite of racers and enthusiasts due to the broad availability of performance parts and the extensive tuning knowledge gained over the past thirty years (has it really been that long?)

Nissan VC-Turbo / Mazda Skyactiv / Hyundai Cvvd – Today

It might seem like a bit of a cheat to give the last spot in our top ten list to a whole group of modern engines, but there are so many new technologies being introduced to production internal combustion engines that we can’t simply ignore their effect on the landscape. Gasoline direct injection (GDI) was the first to become relatively commonplace, offering both performance and fuel efficiency increases, but compared to what’s come after, it seems almost quaint – after all, Diesel engines have more or less always been direct-injection.

Nissan’s recently-released VC-Turbo engine uses a multi-link connecting rod assembly to provide a continuously variable “static” compression ratio, from 8:1 for turbocharged operation under boost to a miserly 14:1 under low load and atmospheric intake pressure for maximum efficiency.

Tires: Milestar MS932 Sport

Mazda introduced a whole range of new technology under their “SkyActiv” trademark, from the aforementioned GDI to a low-compression (14:1) advanced diesel with two-stage turbocharging to eliminate a large percentage of the particulate and NOx emissions normally associated with compression-ignition engines. They’ve even rolled out a gasoline “SkyActiv-X” engine with two-stage direct fuel injection and variable spark or spark-plus-compression ignition that promises 20-30% greater fuel efficiency.

The “camless” engine has been the holy grail of powerplant design since the middle of the last century, and while certain exotic-but-impractical designs have been proposed or used for pure race engines, and some production engines like BMW’s N55 have implemented systems that can dynamically control cam phasing and variable lift, Hyundai’s Continuously Variable Valve Duration (CVVD) technology comes as close as we’ve seen so far to offering complete control over when and how much a conventional tappet valve opens. While it still relies on mechanical contact between a cam lobe and a follower, it’s a good compromise between practicality and theoretical “perfect” control of valve motion.

We’ve done our best to pick the most significant engine designs without prejudice or favoritism, but we’ve undoubtedly left some of you scratching your heads as to why we overlooked your personal selection in our Top Ten. Make your case in the comments below, and we might just revisit the topic in a future article to mend the error in our ways…